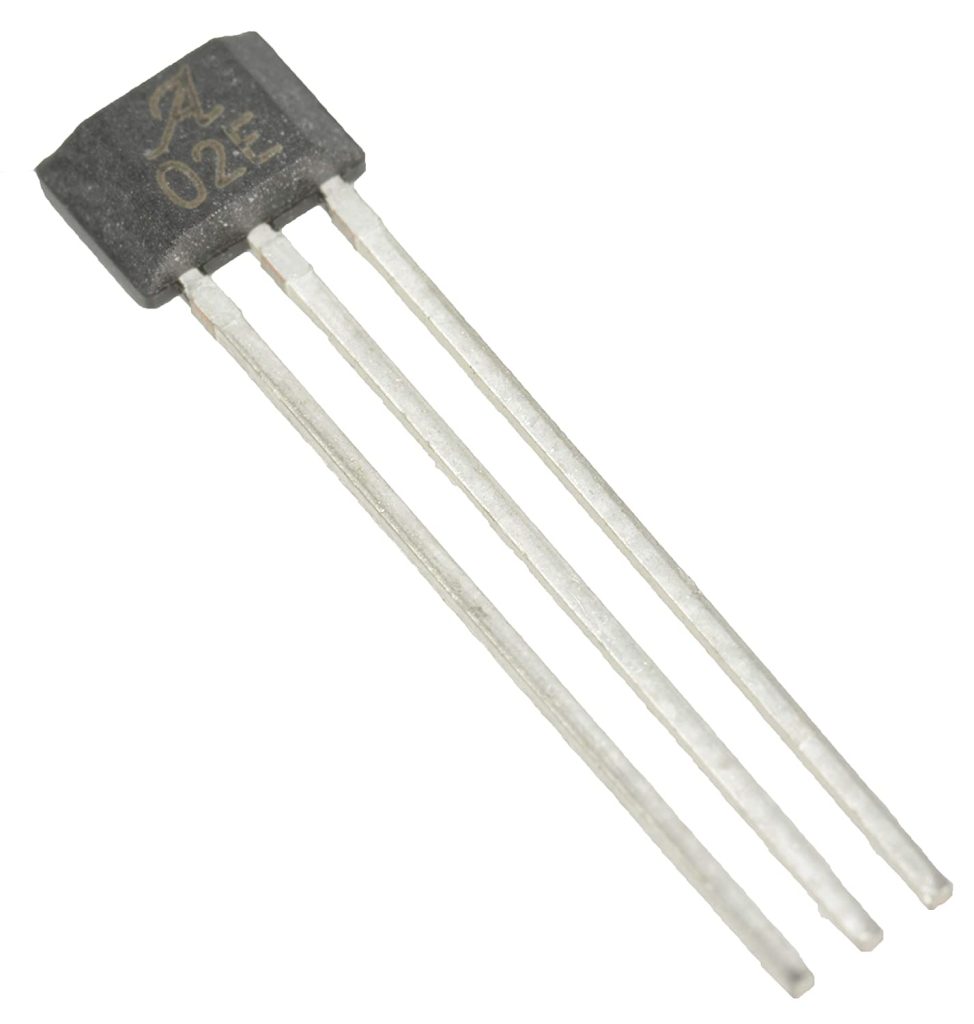

Discover Precision with Proximity Sensors

Precision is a fundamental requirement in numerous industries, from manufacturing and robotics to automotive and aerospace. Achieving and maintaining precision in various processes and systems is essential for both safety and efficiency. Proximity sensors have emerged as indispensable tools for enhancing precision in these applications, offering an innovative solution to detect the presence or absence of objects with remarkable accuracy. These sensors rely on various technologies such as inductive, capacitive, ultrasonic, and photoelectric principles to detect the proximity of an object without physical contact. By providing real-time, reliable feedback, proximity sensors enable automation and control systems to make quick and accurate decisions, ensuring that operations run smoothly, products meet quality standards, and machinery operates safely. One of the key advantages of proximity sensors is their ability to deliver non-contact detection. Traditional mechanical switches or sensors often necessitate physical contact with an object to determine its presence or absence.

Proximity sensors, on the other hand, work without touching the object, minimizing wear and tear and avoiding the risk of contamination. This non-contact detection is particularly crucial in industries where the objects being sensed are delicate or where cleanliness is paramount, such as in semiconductor manufacturing or pharmaceutical production. Proximity sensors help maintain the precision and integrity of these processes. In manufacturing, precision is a paramount concern. Proximity sensors play a pivotal role in quality control and production processes by ensuring that products meet strict tolerances and specifications. These sensors can detect minute deviations in the position of components, allowing automated systems to make instant adjustments, thereby minimizing defects and waste in sensor de efecto hall. Whether it is monitoring the position of a metal sheet on a conveyor belt or the alignment of electronic components on a PCB assembly line, proximity sensors enhance the precision of these manufacturing operations.

In industries like automotive and aerospace, where the demand for high-quality, reliable products is non-negotiable, proximity sensor supplier are integral to the quality assurance process. Proximity sensors also excel in providing precise positional feedback. Robotics and automated machinery rely on these sensors to determine the exact location of objects or obstacles in their path. This information enables robots to navigate intricate environments, pick and place objects with accuracy, and collaborate safely alongside human workers. Proximity sensors make it possible for industrial robots to operate with a level of precision that was once unattainable, driving efficiency, productivity, and workplace safety to new heights. Furthermore, proximity sensors contribute to energy conservation and sustainability efforts. These sensors are designed to be energy-efficient, consuming minimal power during operation. Their ability to detect the presence or absence of objects enables automatic lighting systems to turn off when a room is unoccupied, reducing electricity consumption. In industrial settings, proximity sensors can trigger equipment to power down or enter standby mode when not in use, contributing to significant energy savings.

The right coffee table can transform your living room into a harmonious oasis. It should seamlessly blend with your seating arrangement, creating a sense of balance and flow. Be mindful of the scale and proportion; the coffee table should not dominate the space but complement it. Consider the height in relation to your sofa and the spacing to ensure ease of movement around it. In the grand symphony of interior design, the coffee table plays a crucial role in coffee table manufacturers. It is a reflection of your style, a practical addition to your home, and a catalyst for meaningful interactions. With finesse and attention to detail, your coffee table can unveil the heart of your home, making it a space that is not only beautiful but also deeply personal. So, choose wisely, let your creativity flow, and embrace the transformative power of this seemingly modest piece of furniture.

The right coffee table can transform your living room into a harmonious oasis. It should seamlessly blend with your seating arrangement, creating a sense of balance and flow. Be mindful of the scale and proportion; the coffee table should not dominate the space but complement it. Consider the height in relation to your sofa and the spacing to ensure ease of movement around it. In the grand symphony of interior design, the coffee table plays a crucial role in coffee table manufacturers. It is a reflection of your style, a practical addition to your home, and a catalyst for meaningful interactions. With finesse and attention to detail, your coffee table can unveil the heart of your home, making it a space that is not only beautiful but also deeply personal. So, choose wisely, let your creativity flow, and embrace the transformative power of this seemingly modest piece of furniture.