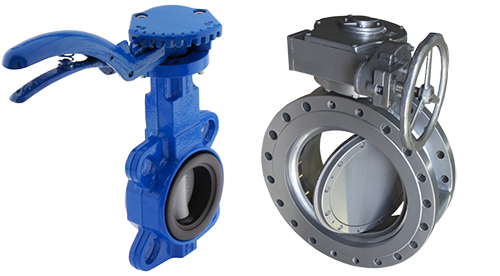

Triple Offset Butterfly Valve Manufacturers in Sustainable and Reliable Valve Solutions

Triple offset butterfly valves are pivotal in many industrial applications due to their superior sealing capabilities and robustness. When selecting a manufacturer for these valves, it is essential to consider both sustainability and reliability to ensure the solutions meet the demands of modern industries while minimizing environmental impact. Sustainable valve solutions involve the integration of eco-friendly practices throughout the manufacturing process. Leading manufacturers in this field are increasingly adopting green technologies and materials to reduce their carbon footprint. For instance, many are transitioning to energy-efficient production techniques and using recyclable materials in their valve components. These practices not only contribute to environmental conservation but also align with global standards and regulations aimed at reducing industrial waste and emissions. Reliability is another critical factor in choosing a triple offset butterfly valve manufacturer.

These Dombor valves are designed to handle high-pressure and high-temperature environments, making their performance crucial to the safety and efficiency of industrial systems. Manufacturers that prioritize reliability invest in rigorous testing and quality control processes to ensure their valves meet the highest standards. This often involves employing advanced materials and manufacturing techniques that enhance durability and performance, reducing the likelihood of valve failure and minimizing maintenance needs. One of the key aspects of a reliable manufacturer is their ability to provide comprehensive support throughout the valve’s lifecycle. This includes offering detailed product documentation, technical support, and responsive customer service. Manufacturers that excel in these areas are better equipped to address any issues that arise and offer solutions that ensure the long-term performance of their valves. Additionally, many leading manufacturers provide customization options to meet specific application requirements, further enhancing the reliability and suitability of their products.

The innovation in valve technology also plays a significant role in the sustainability and reliability of triple offset butterfly valve manufacturers. Manufacturers at the forefront of this innovation are developing valves with advanced features that enhance their efficiency and reduce their environmental impact. For example, some are incorporating smart technology that allows for real-time monitoring and adjustments, improving the operational efficiency of the valves and reducing energy consumption. In summary, the selection of a triple offset butterfly valve manufacturer should be guided by their commitment to sustainable practices and their track record of reliability. Sustainable manufacturers focus on minimizing environmental impact through green technologies and materials, while reliable manufacturers ensure the performance and durability of their valves through rigorous quality control and support services. The integration of innovative technologies further enhances both sustainability and reliability, making these manufacturers ideal partners for industries seeking to balance performance with environmental responsibility.